LulzBot Mini 2 Review: The Best Midrange 3D Printer

Our Verdict

Serious 3D printers will love the speed and flexibility of the LulzBot Mini ii if you're able to find this older model for a decent price.

For

- Prints are fast and of loftier quality

- Supports a wide range of materials

- Printer is quiet

Against

- More expensive than many comparable models

Tom'due south Guide Verdict

Serious 3D printers will love the speed and flexibility of the LulzBot Mini 2 if you're able to notice this older model for a decent price.

Pros

- +

Prints are fast and of loftier quality

- +

Supports a broad range of materials

- +

Printer is quiet

Cons

- -

More expensive than many comparable models

Editors' Note: Nosotros originally publish this LulzBot Mini 2 review in 2018. We've updated pricing and availability info for 2021, just otherwise, this review reflects our testing at the fourth dimension.

Released more than than one-half-a-decade ago, the LulzBot Mini balanced a price that fabricated it attractive to home users with a flexibility to print in multiple materials. The Mini striking the sweet spot for those who are serious well-nigh 3D printing, making it our favorite midrange 3D printer for a long time

The LulzBot Mini 2 ticks those same boxes, simply meliorate, offering a lot of under-the-hood upgrades, such every bit support for flexible printing materials and faster printing. Information technology'southward among the best 3D printers nosotros've tested.

LulzBot Mini 2 review: Price and availability

The LulzBot Mini ii price around $one,500 when it debuted in 2018. These days, the price is a bit higher at virtually retailers, every bit supplies of the printer take dwindled. Withal, Dynamism notwithstanding offers the LulzBot Mini 2 for $1,495.

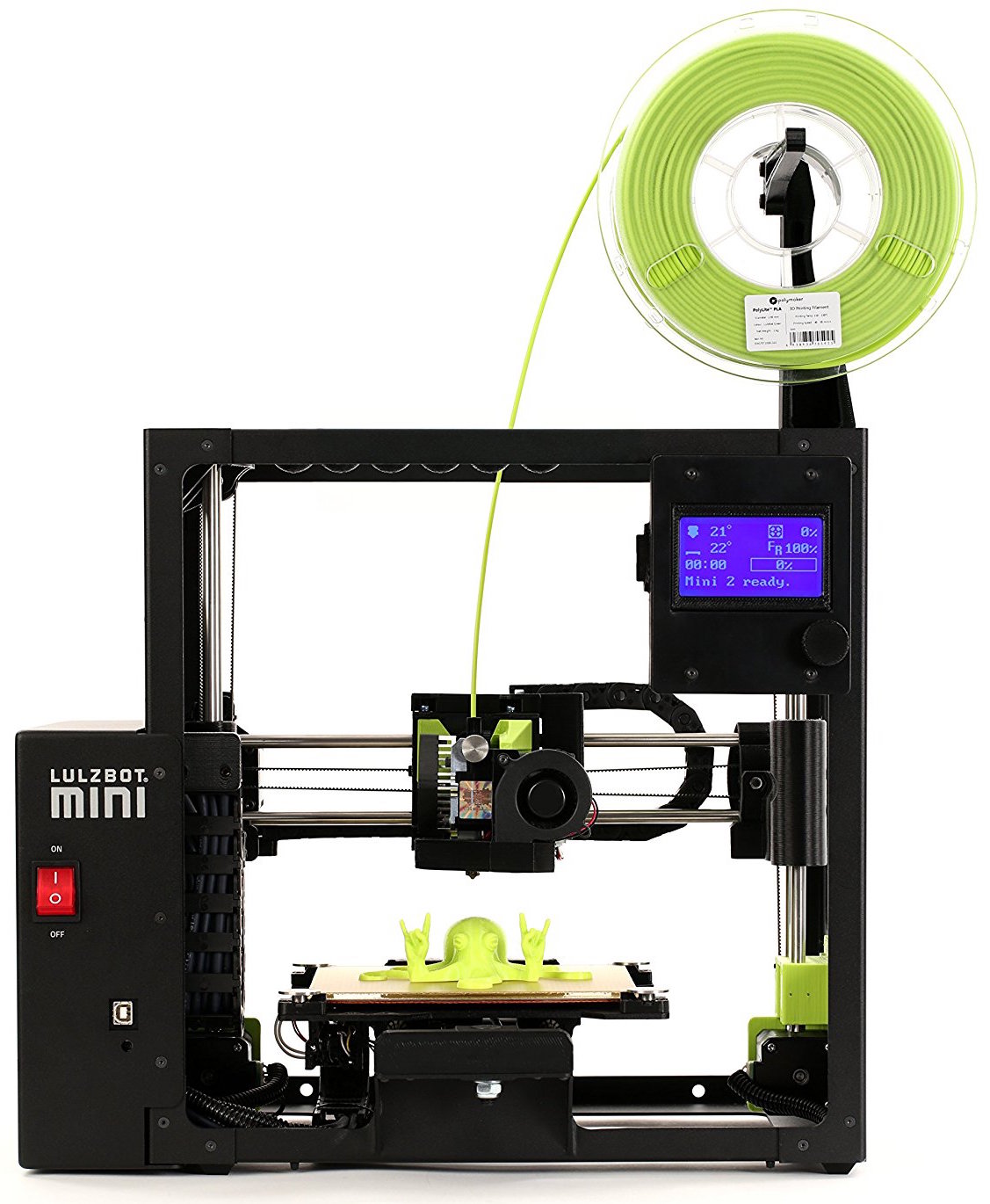

LulzBot Mini 2 review: Design

The Mini two shares the same spare, industrial look equally LulzBot'due south original Mini, putting the focus on press rather than aesthetics. Not that it's an ugly printer: The anodized aluminum frame and 3D-printed parts give the Mini two a clean, functional look.

There'southward some other reason the new printer looks very much like the previous model: well-nigh of the upgrades are on the within. These include a new, more flexible printhead; faster motors; a new modular print bed; and a slightly larger print bed.

The printhead of the LulzBot Mini 2 can feed squishy filaments in without problems.

The new printhead uses a E3D Titan Aero nozzle and a redesigned feeding mechanism, which ways the Mini two can handle flexible materials like Ninjaflex. Previous models required an upgraded printhead to print these since they use a unlike method of feeding the material into the nozzle that heats and melts the filament. The printhead of the Mini two tin feed in these squishy filaments without bug.

The modular print bed on the Mini two also helps with different materials. Some materials (like the PLA material used in most 3D printers) stick all-time to a heated print bed coated with tacky plastic, while others work best on a manifestly glass surface. The Mini 2 offers both: You tin accept out the six.3 10 6.iii-inch glass impress bed and flip it over. One side is coated with PEI plastic, while the other side is uncoated glass. Whichever side is upwards, the print bed can be heated to a toasty 248 degrees Fahrenheit (120 degrees Celsius), so it volition work nicely with materials like ABS that stick ameliorate to a heated print bed. The process of turning the impress bed over does require undoing the hex screws at each corner, merely that doesn't take too long.

The print bed on the Mini 2 is an automobile-leveling one: Every time you lot beginning a print, the printhead touches the four washers that hold the print bed in place to detect the height of the impress bed. In addition, a slice of textile at the back of the impress bed wipes off the printhead, removing whatever stray material that could clog upward the printhead.

The print bed is a footling larger than it was on the original Mini, providing a print area of half-dozen.3 x vi.iii ten 7 inches, for a total impress volume of 281 cubic inches. That is big enough for most things, but it can be limiting. For instance, I was unable to print a case for an iPhone vii Plus, every bit it wouldn't fit onto the print bed. My only options were to tilt the case up (which wasted a huge corporeality of fabric for the supports) or cut the print into two parts.

LulzBot Mini 2 review: Controls

The Mini two can exist controlled either through an LCD screen on the printer or via the free LulzBot edition of Cura.

The LCD screen and dial control on the front of the printer allow you to access any of the controls and features of the printer. By turning the knob and pressing in, you lot can footstep through the card organization to load filament, set temperatures or print files from the SD card. So y'all can use the Mini ii as a stand-lone device without connecting it to a PC over a USB connectedness if you want.

The more flexible mode to command the printer is through the LulzBot version of the open up-source plan Cura, available for Windows, macOS and Linux. This program allows you to load 3D models in a number of formats (.STL, .OBJ and others) and set up them for printing.

You tin scale, rotate and join models together, preparing multiple models to print at one time. These models are presented in a 3D view, which allows you to move around and zoom in or out, which is useful for spotting any potential press problems. When the model is loaded, the program automatically creates the printing file (a process called slicing), and you can then view a preview of the printing process, layer by layer. You can tweak this process to a very fine degree, controlling if supports are added to concur the impress in identify during printing. You can also control how dense these supports are, along with many other options. Alternatively, y'all can let Cura exercise the difficult work using one of the 34 included profiles for unlike materials from standard PLA to nylon.

LulzBot Mini 2: Printing operation

Printing itself is very quiet, with the LulzBot Mini 2 making only a low squeaking dissonance as the printhead moved around.

In one case you've prepared your model, you can print it over the USB connection, or salvage the print file to an SD Card and insert that into the printer. Either manner, we establish that the printing process was simple and generally problem-free. We printed dozens of models in a number of materials and had only a couple of failures when the impress material didn't adhere to the print bed.

Printing itself is very quiet, with the Mini 2 making only a low squeaking dissonance as the printhead moved around. In fact, my wife dislocated it with a mouse, wondering if our cats had defenseless something in my office when I left the printer running.

LulzBot Mini 2 review: Print materials

There are no restrictions on what type of 3mm filament you can use with the Mini ii, and LulzBot provides an excellent set of guidelines for many types. The upgraded extruder and modular print bed make it significantly more flexible than most 3D printers, with the ability to use flexible filaments such as Ninjaflex or PolyFlex that unremarkably crave different printing heads. (Models printed with these materials are soft and flexible, like rubber.)

The Mini ii tin also handle materials like Nylon or the stone and wood filaments that take broad-ranging requirements of temperature and impress-bed blazon.

LulzBot Mini 2 review: Print speed

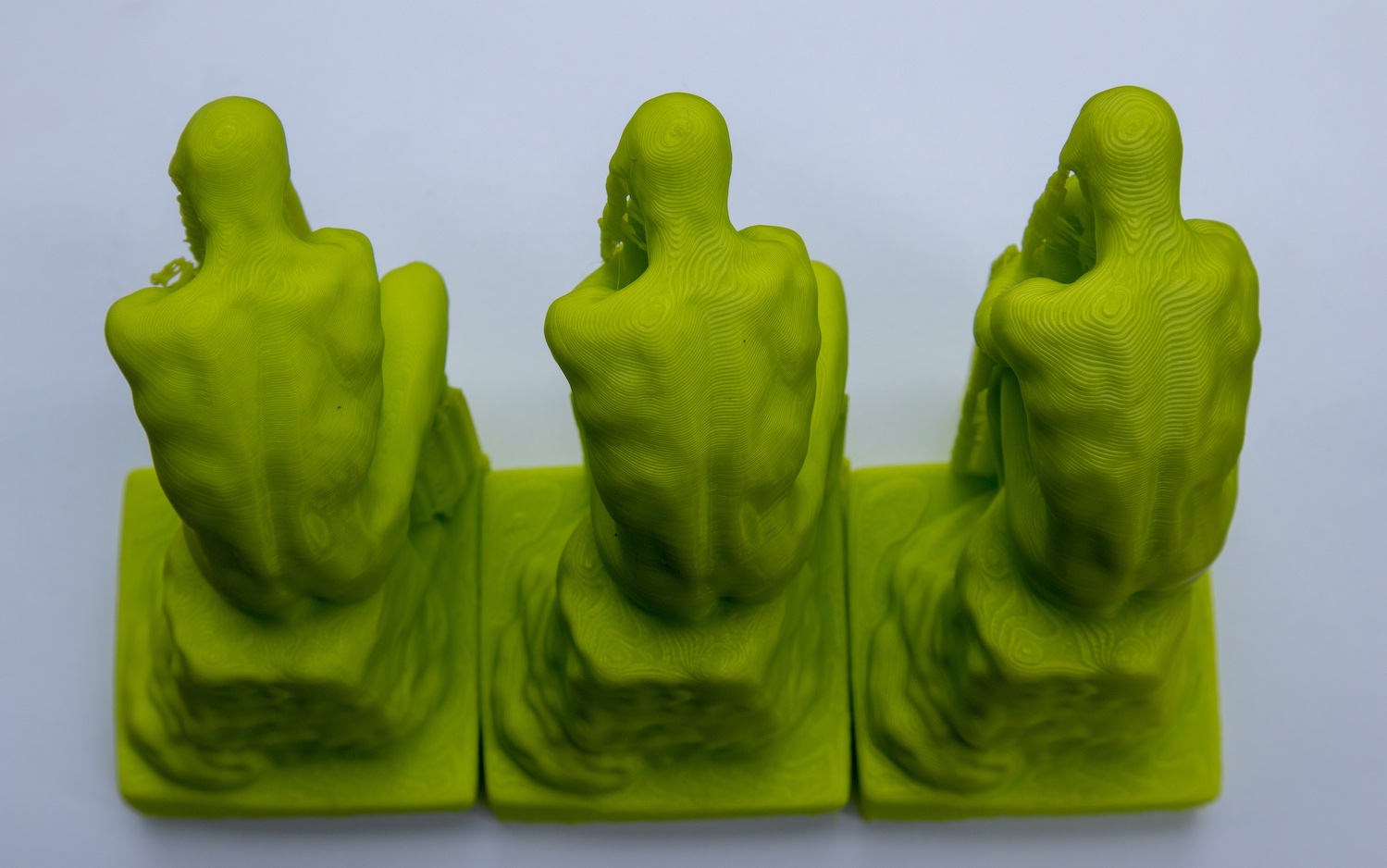

We constitute that the Mini two was significantly faster at printing than the original Mini, printing out our four.five-inch-high Thinker model in between three hours and seven minutes in loftier-speed mode and 6 hours and 37 minutes at high quality. That'southward about an hour faster on the highest quality than the original Mini, and much faster than cheaper printers such every bit the da Vinci Nano, which took more than than 21 hours to print at the highest quality.

If you lot program to utilise your 3D printer a lot, the Mini 2's combination of high speed at high quality could be a significant time-saver.

LulzBot Mini 2: Print quality

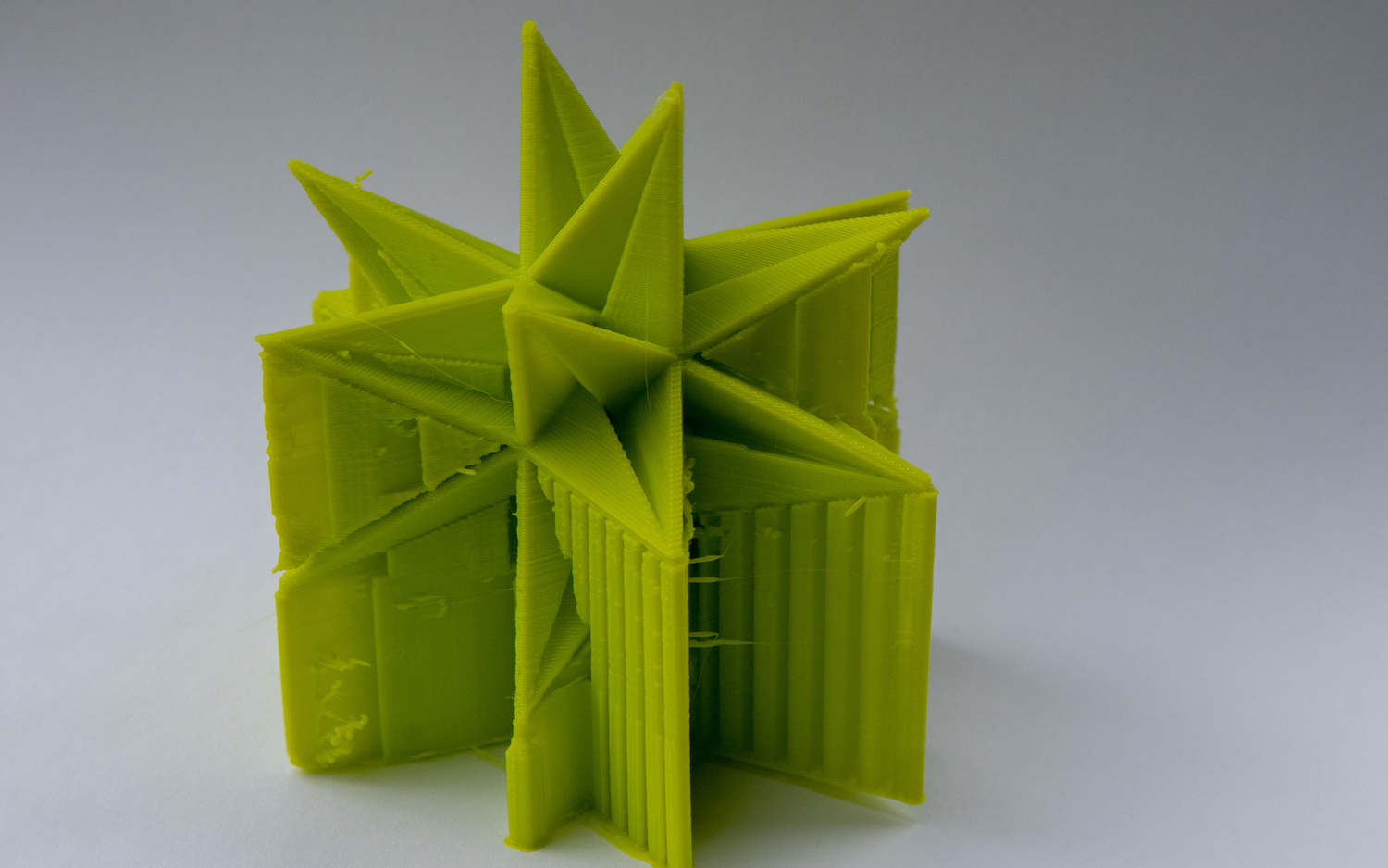

We found that the Mini 2 produced high-quality prints across the board, yielding fantabulous prints from our test models that offered good detail and very few issues.

The Mini reproduced the details of our Thinker test model accurately in all print modes, although the layering on the fast-impress modes was very visible. The same was true of our geometric sculpture model, which had lots of sharp edges and points. The Mini 2 had no trouble with these, producing polish edges and sharp points in this circuitous and hard print. The same was true of our test print of a set of planetary gears, which fitted together easily subsequently removing and cleaning.

We did notice that prints fabricated with flexible cloth had a lot of whiskering, though, where thin whiskers of filament are left attached to the print as the printhead moves. To be off-white, these were not difficult to remove, and this was with the default settings for this material; we could probably have removed them with some tweaks to the temperature and print speed.

LulzBot Mini 2 review: Verdict

The LulzBot Mini 2 is a more than than worthy successor to the original Mini. It's a fast, flexible printer that can produce high-quality prints in both the standard ABS and PLA filaments, as well as work with a wider range of materials than most printers.

That speed and flexibility comes at a cost, though. At $one,500 originally, the Mini ii costs substantially more than lower-end printers like the da Vinci Nano and midrange models like the Dremel DigiLab. Just if you want faster prints fabricated of a wide variety of materials, the extra cash information technology costs you for the LulzBot Mini 2 is more than worth information technology.

Source: https://www.tomsguide.com/us/lulzbot-mini-2-3d-printer,review-5673.html

Posted by: wardnearst.blogspot.com

0 Response to "LulzBot Mini 2 Review: The Best Midrange 3D Printer"

Post a Comment